By W. Jon Wallace, CSP, MBA

Article published in ASSE by W. Jon Wallace:

Flammable and combustible liquids are present in nearly every workplace. Gasoline, diesel fuel, and many common products like solvents, thinners, cleaners, adhesives, paints, and polishes may be flammable or combustible. Flammable and combustible liquids play a part in our lifestyle. However, if used or stored improperly, serious fires and death may occur. This article discusses flammable and combustible liquid terminology, handling, and storage practices.

The applicable OSHA standard is 29 CFR 1910.106–Flammable Liquids, which is based upon the 1969 version of NFPA® 30 Flammable and Combustible Liquids Code. However, it is important to note that in 2012, in response to OSHA’s revised Hazard Communication standard (due to incorporation of the Globally Harmonized System [GHS]), OSHA revised 29 CFR OSHA 1910.106. The title of 29 CFR 1910.106 has been changed from “Flammable and Combustible Liquids” to “Flammable Liquids.” One significant change is the revised regulation lists liquids as “categories” rather than “classes.” However, the 2012 Edition of NFPA® 30 has not been revised to reflect GHS guidelines. For instance, NFPA® 30 continues to use the term flammable and combustible liquid and refers to “classes” of liquids.

If you are covered by OSHA, you must comply with 29 CFR OSHA 1910.106 – Flammable Liquids. As a best practice, however, it is recommended that you review both OSHA 1910.106 as well as NFPA® 30 and comply with the standard providing the highest level of protection.

Terminology

A review of the properties and hazards of flammable and combustible liquids is in order.

Autoignition Temperature: The autoignition temperature is the lowest temperature at which a liquid will ignite without an external ignition source. While most flammable and combustible liquids have autoignition temperatures in the range of 500°F to 1000°F, some have very low autoignition temperatures. For example, ethyl ether has an autoignition temperature of 356°F, and its vapors have been ignited by heated surfaces.

Flashpoint: This is the minimum temperature of a liquid at which sufficient vapor is given off to form an ignitable mixture with the air, either near the surface of the liquid or within the vessel used.

Fire Point: The fire point is the lowest temperature at which a liquid will ignite and achieve sustained burning when exposed to a test flame.

Vapor Pressure: Pressure, measured in pounds per Square inch–absolute (psia), exerted by a liquid.

Combustible Liquid (perNFPA® 30): A combustible liquid has a flashpoint at or above 100°F. Combustible liquids are subdivided into Class II or Class III liquids:

| Class | Flashpoint | Examples |

| Class II | > 100° F and < 140° F | Diesel fuel, fuel oil, kerosene, motor oil |

| Class IIIA | > 140° F and < 200° F | Furfural, linseed oil, mineral oil, oil-based paints |

| Class IIIB | > 200° F | Ethylene glycol, glycerine, neatsfoot oil |

Flammable liquid (perNFPA® 30): A flammable liquid is a liquid with a flashpoint below 100° F. Flammable liquids are subdivided into Class IA, IB, or 1C liquids:

| Class | Flashpoint | Boiling Point | Examples |

| Class IA | <73° F | <100° F | Ethyl ether, heptane, pentane, propylene oxide, vinyl chloride |

| Class IB | <73° F | > 100° F | Acetone, ethanol, gasoline, isopropyl alcohol, methanol, methyl ethyl ketone, octane, toluene |

| Class IC | > 73° F and <100° F | All boiling points | Isobutyl alcohol, mineral spirits, styrene monomer, turpentine, xylene |

Flammable Liquid (per OSHA 1910.106): A liquid with a flashpoint at or below 199.4° F. (93° C). Flammable liquids are divided into four (4) categories:

| Category | Flashpoint | Boiling Point |

| 1 | < 73.4° F (23° C) | ≤ 95° F (35° C) |

| 2 | < 73.4° F (23° C) | > 95° F (35° C) |

| 3 | ≥ 73.4° F (23° C) and ≤ 140° F (60° C) | |

| 4 | > 140° F (60° C) and ≤ 199.4° F (93° C) |

Lower Explosive Limit (LEL): The minimum vapor concentration (by percent) in which a liquid can form an ignitable mixture in air is called the “lower explosive limit.” Below this limit, vapor concentration is too lean to support combustion.

Upper Explosive Limit (UEL): The maximum vapor concentration (by percent) in which a liquid can form an ignitable mixture in air is called the “upper explosive limit.” Above this limit, vapor concentration is too rich to support combustion.

Explosive Range: The range between the LEL and UEL is the “explosive range.” If a source of ignition such as a flame, spark, or static electricity is present, an explosion may occur. This may also be referred to as the “flammable range.” The graph below illustrates the explosive range of gasoline.

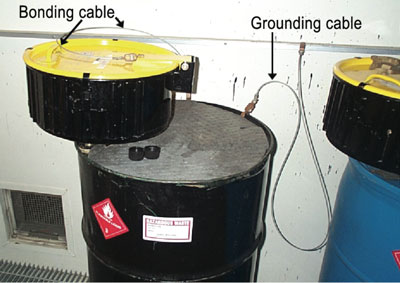

Grounding and Bonding: When flammable and combustible liquids travel through a pipe or through the air, static charges are accumulated. Grounding and bonding is necessary during the transfer of flammable liquids that have a flashpoint below 100° F to prevent a static spark from igniting the flammable vapors. An example of grounding and bonding is illustrated in the photograph below.

Author’s collection—Above photo illustrates flammable solvent being placed inside a 55-gallon waste drum. Funnel is bonded to drum and drum is grounded.

Read the article below for an excellent overview of grounding and bonding requirements.

Container: Any vessel with a capacity of 60 U.S. gallons or less that is used for transporting or storing liquids is referred to as a “container.”

Portable Tank: Any closed vessel having a liquid capacity over 60 U.S. gallons and not intended for fixed installation is called a “portable tank.”

Safety Can: A safety can is a listed container with a capacity of no more than 5 gallons that has a spring-closing lid and spout cover and is designed to safely relieve internal pressure when exposed to fire.

Flammable Storage Cabinet: A “flammable storage cabinet” is a listed storage cabinet designed in accordance with NFPA® 30: 9.5.3 (1). Such a cabinet is designed and constructed to limit the internal temperature to no more than 325°F from the center of the cabinet to within 1 inch of the top of the cabinet when subjected to a 10-minute fire test.

Fire Area: A “fire area” is an area of a building separated from the remainder of the building by special construction. This area has a fire resistance of at least 1 hour and has all communicating openings properly protected by an assembly that also has a fire resistance rating of at least 1 hour.

Storage

Storage of flammable and combustible liquids is usually a necessity. Whenever flammable and combustible liquids are stored improperly, however, they become a significant fire hazard. For instance, NFPA® 30: 17.6.9 prohibits Class I flammable liquids from being stored in a basement. 29 CFR 1910.106 has established the following storage practices to ensure flammable liquids are not stored in excessive quantities.

| Maximum Quantities Outside of a Flammable Storage Cabinet or Inside Storage Room | |

| Category and Container Type | Quantity |

| Category I Liquids in Containers | 25 Gallons |

| Category 2, 3, or 4 Liquids in Containers | 120 Gallons |

| Category 2, 3, or 4 Liquids in a single Portable Tank | 660 Gallons |

| Maximum Quantities Inside of a Flammable Storage Cabinet or Inside Storage Room | |

| Category of Liquid | Quantity |

| Category 1, 2, or 3 | 60 Gallons |

| Category 4 | 120 Gallons |

Flammable Storage Cabinets—To vent or not to vent?

When I teach courses on flammable and combustible liquids, I am repeatedly asked the question: “Are we required to vent the bung on a flammable storage cabinet?”NFPA® 30: 9.5.4 does not require bungs to be vented. In addition, in a correspondence to Mr. Mark E. Graham dated March 28, 1978, NFPA provided a formal position concerning the issue of venting flammable storage cabinets: “The vents for flammable liquids storage cabinets are not required or even recommended by our Flammable and Combustible Liquids Code, NFPA® 30…”

“The fittings are sometimes provided by the manufacturers due to the fact that, in a few locations in the country, local ordinances require such vents to be provided. Therefore, the manufacturers plug these vents [with plugs] which can be removed in those few areas where such venting is required.”

Unless a municipality or other government agency specifically requires the bung to be vented, venting is not required, nor is it recommended.

Handling Liquids at Point of Final Use

To understand flammable liquids it is important to know that it is the vapor, not the liquid that burns. For instance, explosions routinely occur when mechanics drain a gasoline tank and mistakenly assume it is safe to commence repairs involving welding and/or brazing on the tank. Although the tank is empty, its vapor space contains gasoline vapors. If the vapor concentration is within the explosive range and a source of ignition is introduced, an explosion will likely occur.

The following work practices must be followed when handling flammable and combustible liquids:

- Flammable liquids with a flashpoint below 100° F must be kept in covered containers when not in use.

- Flammable liquids must be stored only in acceptable containers.

- Grounding and bonding must be utilized when transferring flammable liquids with a flashpoint below 100° F.

- Locations where flammable vapor-air mixtures may exist must have electrical wiring installed according to the requirements of 29 CFR 1910 Subpart S (Electrical):

—Flammable vapor-air mixtures may exist under normal conditions: Class I Division I

—Flammable vapor-air mixtures may exist under abnormal conditions: Class I Division II - Where flammable or combustible liquids are used or handled, except in closed containers, means shall be provided to dispose of leaked or spilled liquid promptly and safely.

- Flammable or combustible liquids shall be drawn from or transferred into vessels, containers, or portable tanks within a building by one of the following methods:

(1) Through a closed piping system

(2) From safety cans

(3) By means of a device drawing through the top

(4) From containers or portable tanks by gravity through an approved self-closing Valve - Transfer operations must be provided with adequate ventilation. Sources of ignition are not permitted in areas where flammable vapors may travel.

- Transferring liquids by means of air pressure on the container or portable tanks is prohibited. This type of transfer may result in an overpressure that could exceed what the container or tank is designed to withstand. In addition, a flammable atmosphere could be created within the container or tank. This atmosphere would be particularly sensitive to ignition because of the increased pressure.

Please remember that this is a general overview of flammable and combustible liquids. For more information, refer to 29 CFR 1910.106 Flammable Liquids as well as NFPA® 30 Flammable and Combustible Liquids Code.

If you have any questions concerning this article or other safety issues, please contact W. Jon Wallace, “The Safety Guru”, at 919.933.5548 or by e-mail