Do I have combustible dust in my facility? What is a combustible dust? Due to recent combustible dust explosions, as well as OSHA’s national emphasis program on combustible dust, there is a heightened awareness and confusion concerning combustible dust hazards. The first question as part of a combustible dust evaluation is whether combustible dusts are present at your facility.

NFPA 654 (2013 Edition): “Standard for the Prevention of Fire and Dust Explosions from the Manufacturing, Processing, and Handling of Combustible Particulate Solids” defines a combustible dust as follows: “A finely divided combustible particulate solid that presents a flash fire hazard or explosion hazard when suspended in air or the process-specific oxidizing medium over a range of concentrations.” In addition, a combustible particulate solid is defined as: “Any solid material composed of distinct particles or pieces, regardless of size, shape, or chemical composition that presents a fire hazard.”

Examples of combustible dust:

- Metal Dust – Such as Aluminum and Magnesium

- Wood Dust

- Coal and Other Carbon Dusts

- Plastic Dust and Additives

- Biosolids

- Organic Dust – Sugar, Flour, Paper, Soap, Dried Blood (e.g., slaughterhouses)

- Certain Textile Materials

If you are handling and processing any of these dusts, you may have a combustible dust issue at your facility.

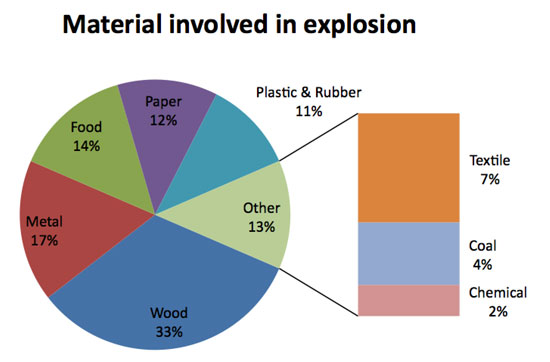

The following chart illustrates the types of material involved in combustible dust explosions.

Source: Combustible Dust Policy Institute

Listed below are typical Industries handling combustible dust:

- Agriculture

- Food Products

- Chemicals

- Textiles

- Forest and Furniture Products

- Metal Processing

- Tire and Rubber Manufacturing

- Paper Products

- Pharmaceuticals

- Wastewater Treatment

- Recycling Operations (metal, paper, and plastic)

- Coal Dust – Coal Handling and Processing Operations

Summary

The first step of the combustible dust assessment is determining if you have any combustible dust present at your facility. The next step is an evaluation to determine if the dust is handled or processed in a manner that could potentially create a combustible dust hazard. If you determine combustible dust is a potential issue, a combustible dust program should be implemented based upon OSHA’s national emphasis program on combustible dust: CPL 03-00-008, NFPA 654: “Standard for the Prevention of Fire and Dust Explosions from the Manufacturing, Processing, and Handling of Combustible Particulate Solids,” as well as NFPA 61: “Standard for the Prevention of Fires and Dust Explosions in Agricultural and Food Processing Facilities.“

If you have any questions concerning this article or other safety issues, please contact W. Jon Wallace, “The Safety Guru”, at 919.933.5548 or by e-mail